|

Victan®

XTH

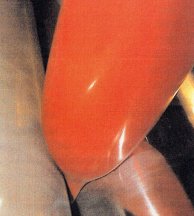

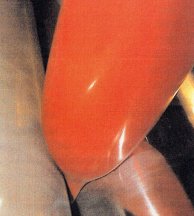

Victan® XTH was the first multilayer oriented

casing of the victan-brand. The X prefix stands for the term eXtreme,

as in extremely capable. The multilayer structure allows the casing

to be all things; extra strong, enhanced diameter control, high

shrink, low solute permeability, and brilliant color. Its analog,

XLH, is a lighter form of the casing used when additional pliability

is required.

|

|

Victan®

XTH is the standard product with all the mentioned properties

and relatively high adhesion to the meat mass. This high cling

suggests that the chief use for the casing to be those recipes

which tend to "fat-out" or form jelly deposits. Proper use of

victan® XTH for such products will result

in the proper thickening and setting of the emulsion. |

Victan®

XTM

Victan® XTM is a special product with characteristics

similar to victan® XTH.

The chief difference is the level of meat cling. Here the M designation

in XTM stands for medium (cling). So this product would be used in

circumstances where recipes are generally higher in protein and lower

in fat. Its analog, XLM, is a lighter form of the casing used when

additional pliability is required.

Victan®

XTE

Victan® XTE is a special product with characteristics

similar to victan® XTH. The

chief difference is the level of meat cling. Here the E designation

in XTE stands for Easy-peel (little or no cling). So this product

would be used with protein or binder-rich recipes that would adhere

too heavily to standard nylon casings. Its analog, XLE, is a lighter

form of the casing used when additional pliability is required.

victan®

KB

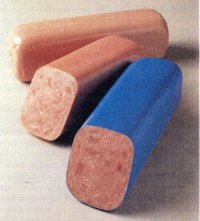

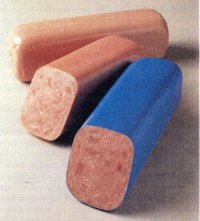

Victan®

KB is our strongest non-oriented casing and is meant for production

of cooked products (pasteurized/sterilized) requiring superior diameter

control. Victan® KB is suitable for use in

production of large diameter emulsion-type sausages especially those

with dense meat mass. Firm stuffing and clipping, and pre-soaking

of the material are conditions for obtaining a wrinkle-free surface

of the finished product. The shelf-life of victan®

KB, as with most single-layer materials, is on the order of several

weeks. High turnover retail packaging, or in addition to in-house

slice-n-pack operations are good niches for this product. Victan®

KB is available in both high-gloss or matte surface finishes.

victan®

P

Victan® P was conceived specifically for the

use of meat products under slack filling conditions. In this way the

finished product, whether it be an emulsion-type meat loaf, or a cooked

cured ham, takes the shape of the mould in which it is placed. The

expansion of the meat product into the mould shape is only fully realized

after a complete cooking and cooling cycle.

| |

Victan®

P is also available in perforated form. This allows air trapped

during the stuffing and clipping operation, in addition to jelly

formed during, cooking to escape through the barely visible

regularly - patterned perforations. In such cases, shelf-stability

is typically achieved through the use of an over wrap. Other

types of cooked sausage, such as corned beef, blood sausage,

and tongue can be produced in Victan®

P without perforation. Victan® P is available

in both high-gloss or matte surface finishes. |

|

|

victan® PT

Victan® PT was initially created for the use

of European-Style spreadable sausages and other raw-meat and non-cooked

products. However, in North America the chief uses are in the dairy

(cheese and butter), fish, frozen food, and pet food industries.

These food specialists can use the casings to obtain either supermarket-type

retail products or as an intermediary packaging in their industrial

large portion processing for further processing and/or consumer-size

packing. Victan® PT is available only in high-gloss

finish and is typically transparent.

|

|